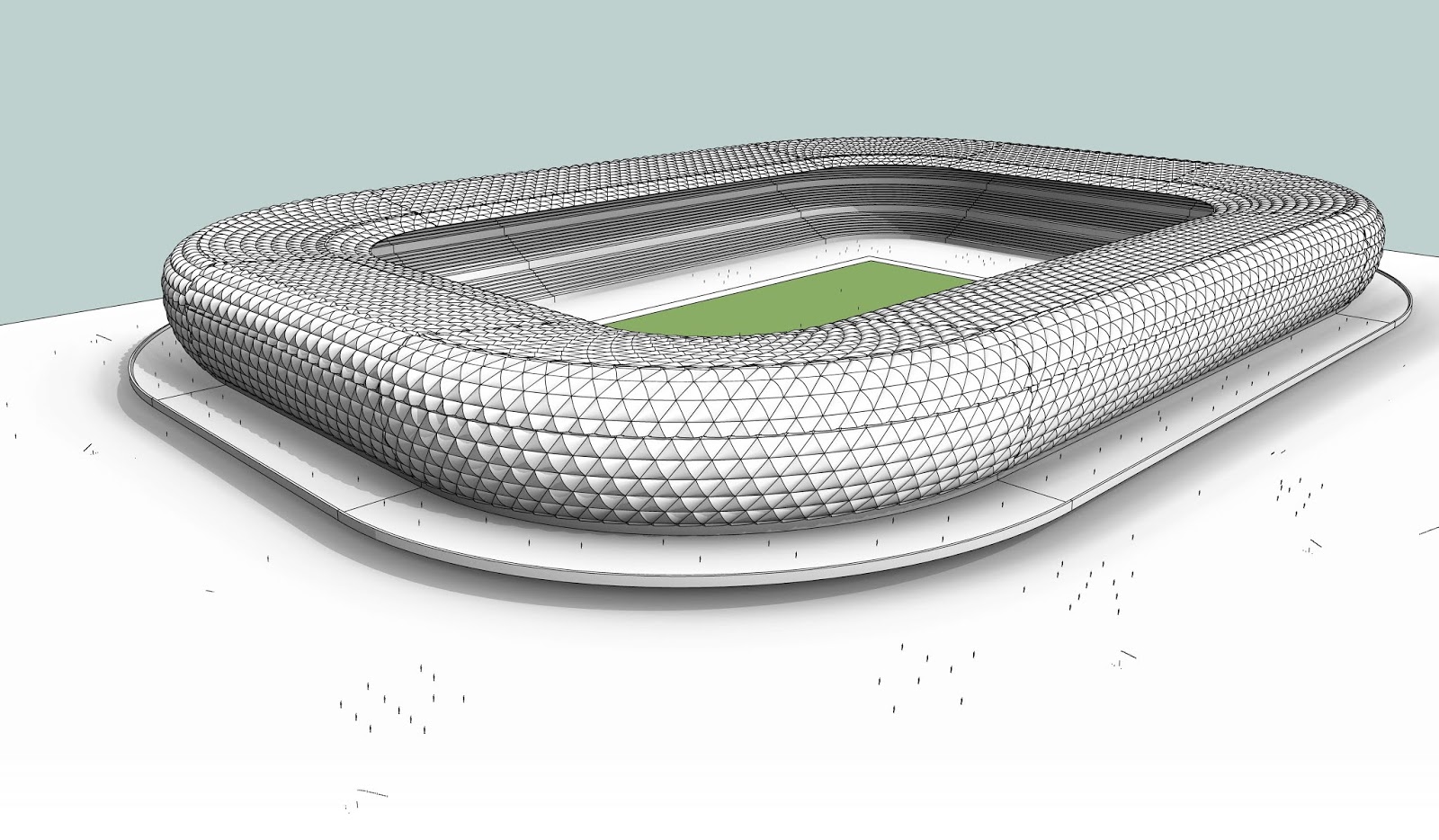

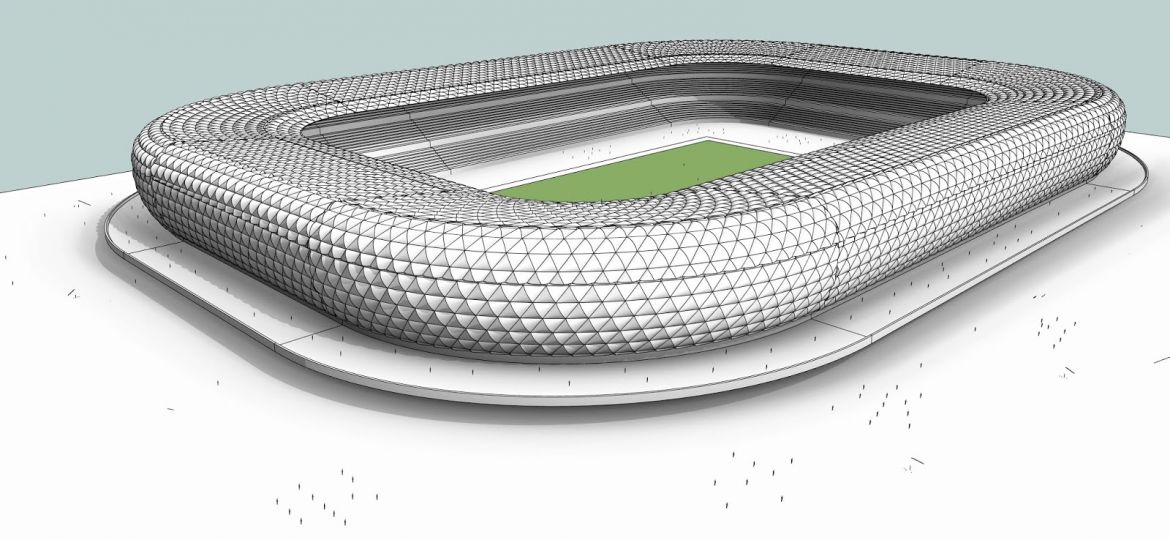

Nothing says passion like a grand Arena designed to be a prominent stop for diverse sporting activities that bring pleasure to loyal sports enthusiasts. This is what the Allianz Arena was created for. We’ll be showing you how Hassan Anifowose, Architect and Co-founder at Chronos Studeos implemented the parametric 3d modelling process for Allianz Arena.

The Process

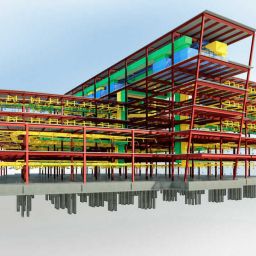

The modelling process was implemented using Revit.

01. Defining the Intent

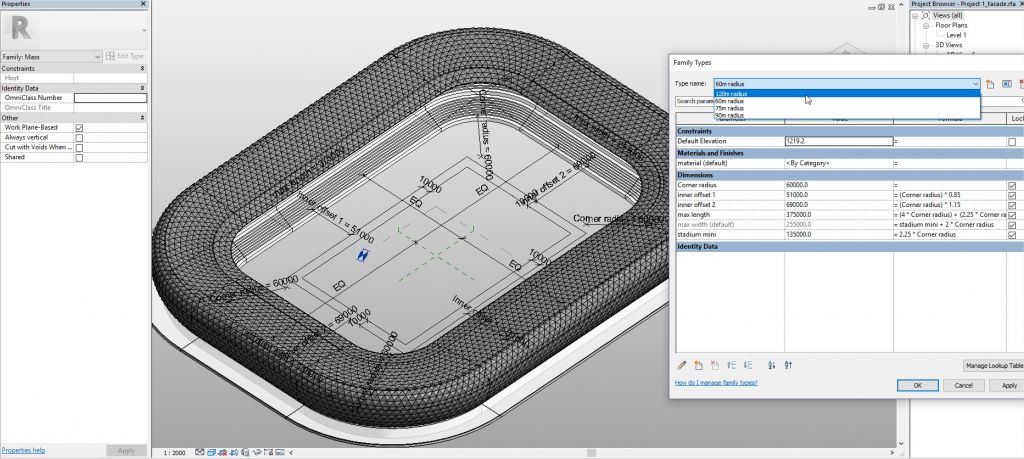

A very essential step for every project setting a clear intention for the outcome and its purpose as this will guide whatever you do next. The aim was to create a final product useful as; a local club football pitch, a standard pitch, and an Olympic size stadium – this establishment guided the series of decisions in the preceding steps.

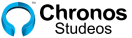

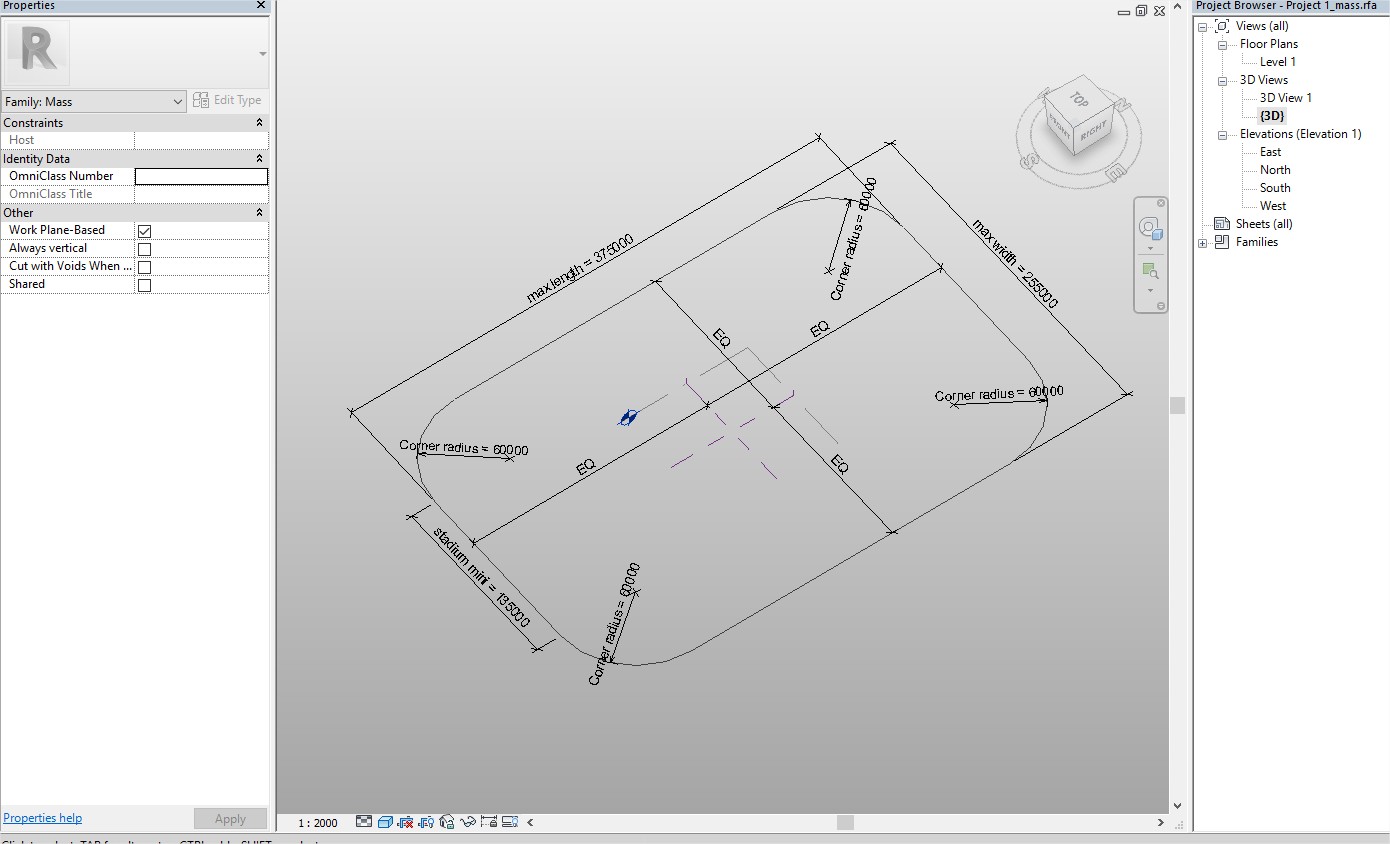

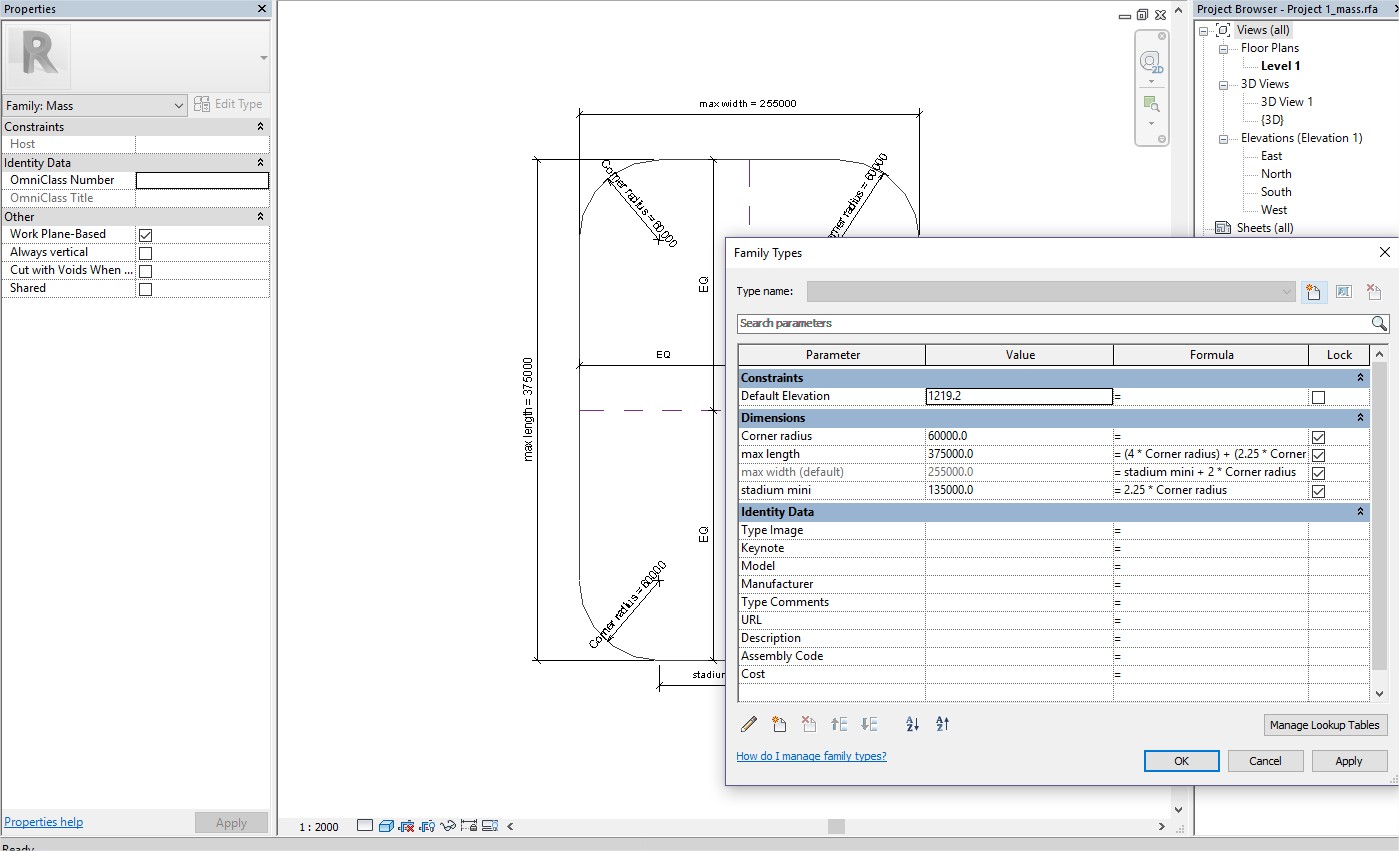

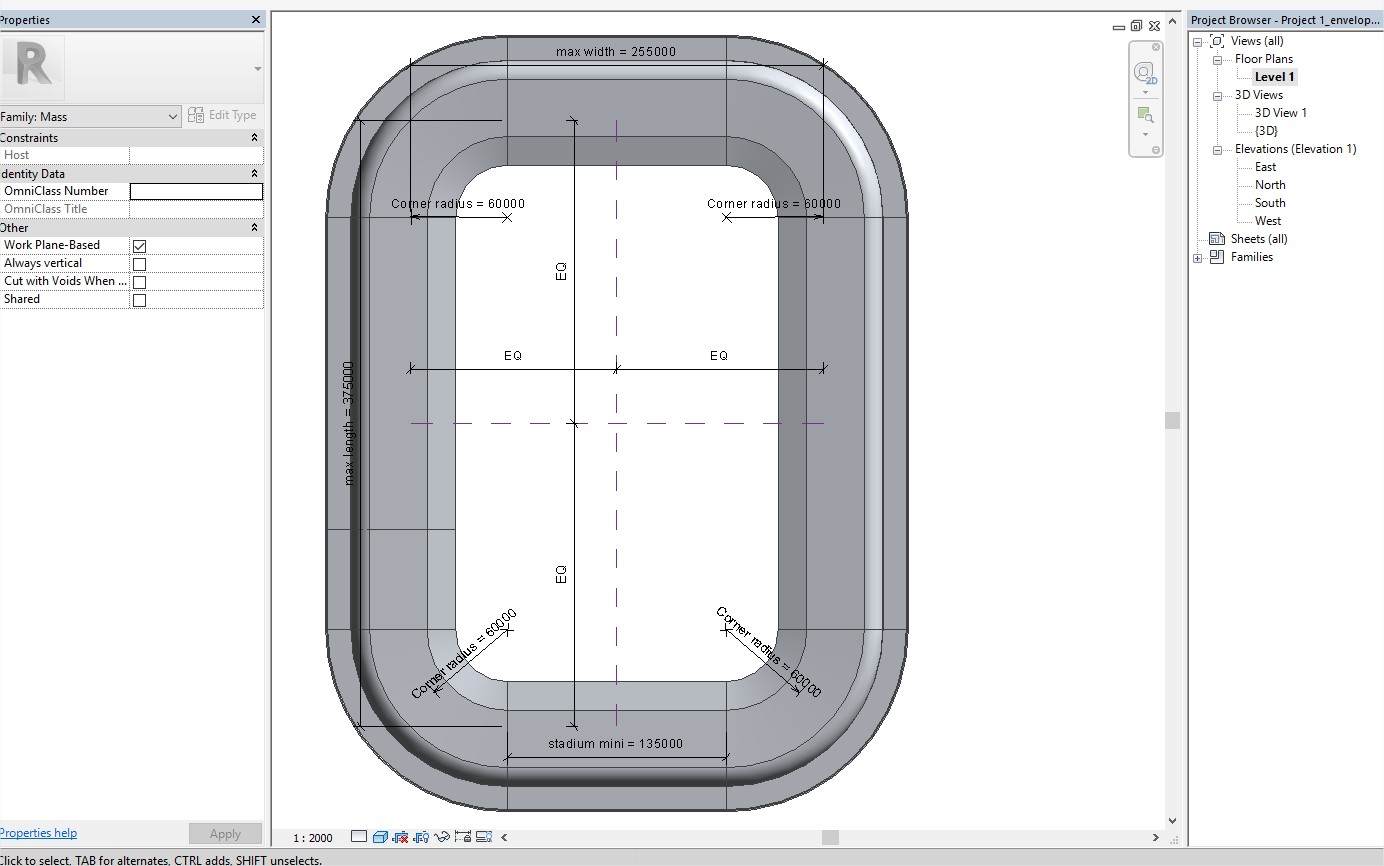

02. Creating the Horizontal Spread

An initial sketch of the stadium outline was created based on the approximate size. For this, a central point was defined with reference lines; the driving parameter being the corner radius which controls the width and length of the stadium, which are equally distant from the centre.

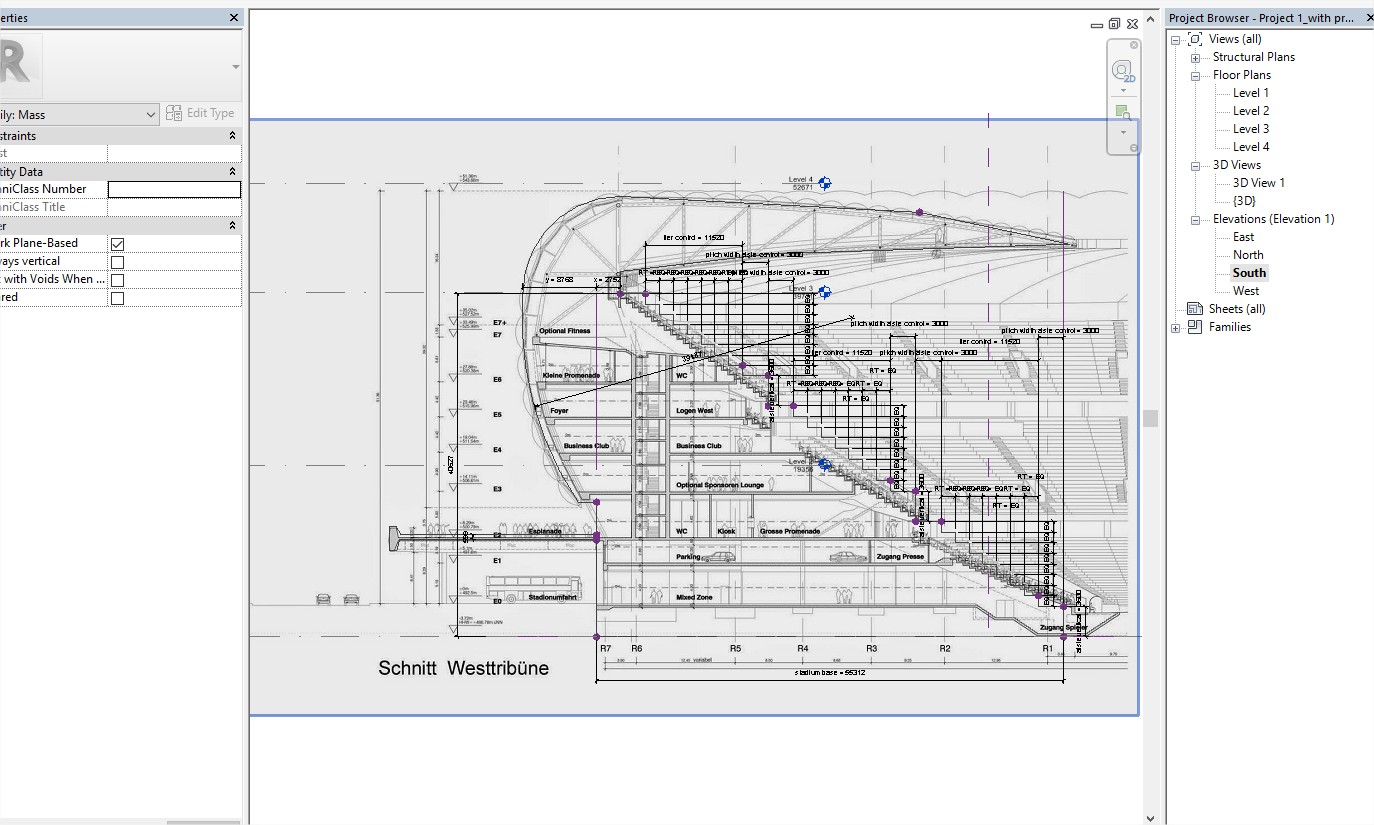

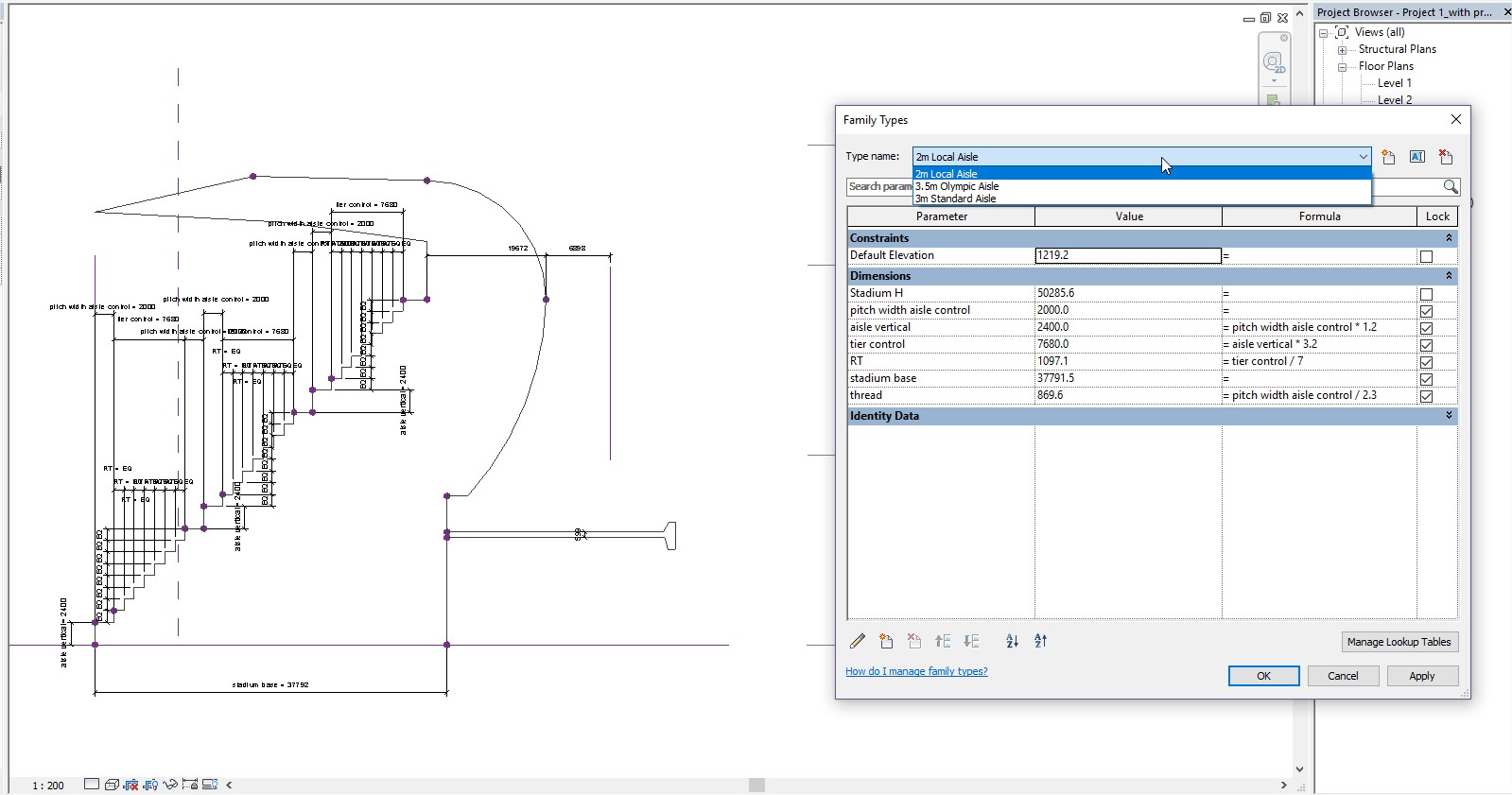

03. Creating the Section Profile

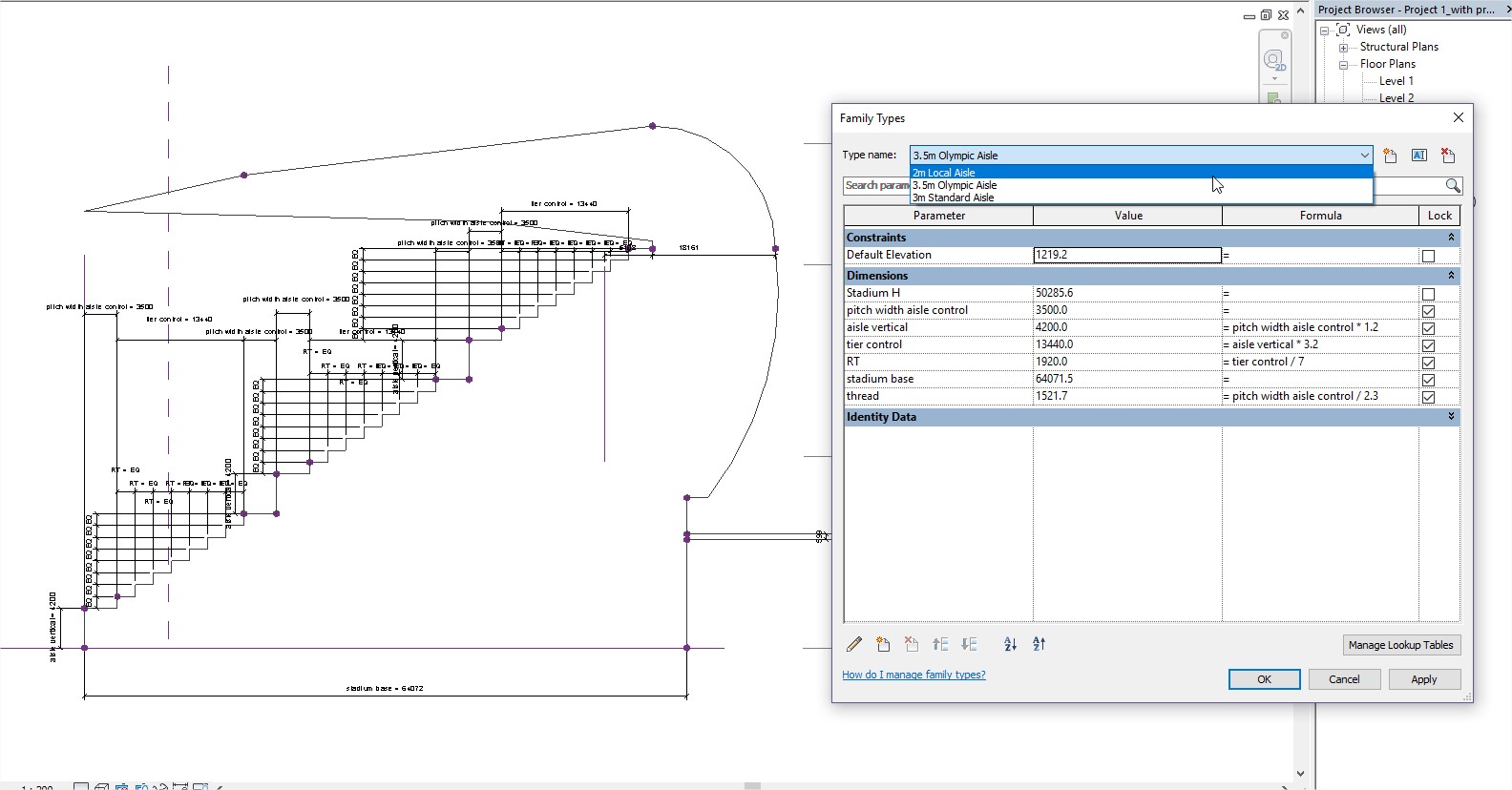

A jpeg image was imported from the Architects’ design drawings to outline the stadium section. Each tier is arrayed with a string of rows demarcated by aisles which control the size modifications for the stadium. Three different aisles were created depending on the usage and expected capacity; and also to flex the parameters. Making each one adaptable.

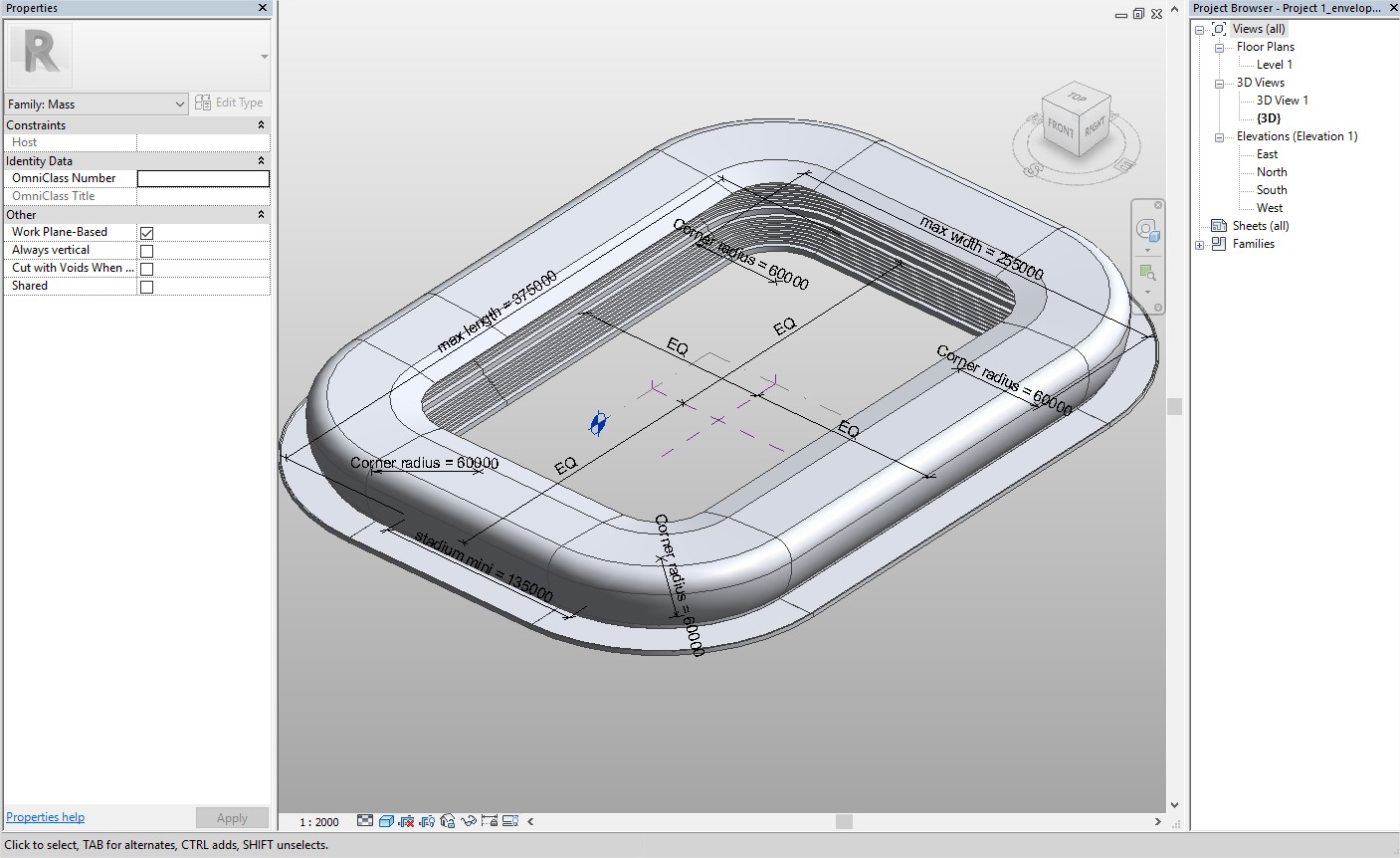

04. Uploading the Section Profile

Next, the “create form” button was used to create the stadium sweep upon appropriate selection of the profile and horizontal spread. The Revit family (section profile) was added into the previous family controlling the horizontal spread of the stadium. Each type was flexed and tested to ensure consistency.

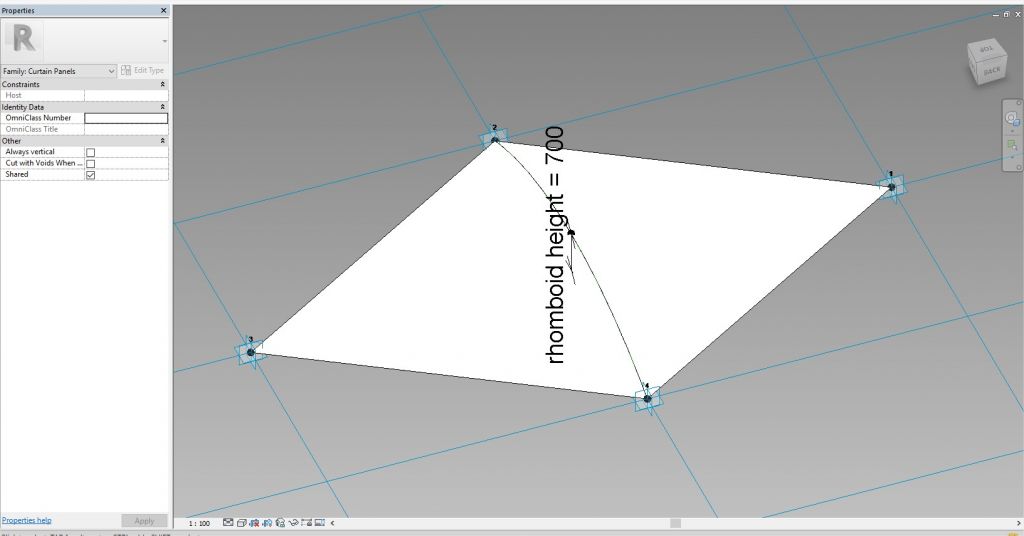

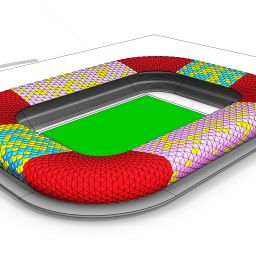

05. Creating the parametric membrane curtain panel

For the outer shell of the section profile, a new parametric Revit family was created and applied to it. The curtain panel was designed as a rhomboid which had height-adjustable parameters. The height was set at 700 from the centre for this project. The face was also created and they were welded together after creating reference lines along the edges.

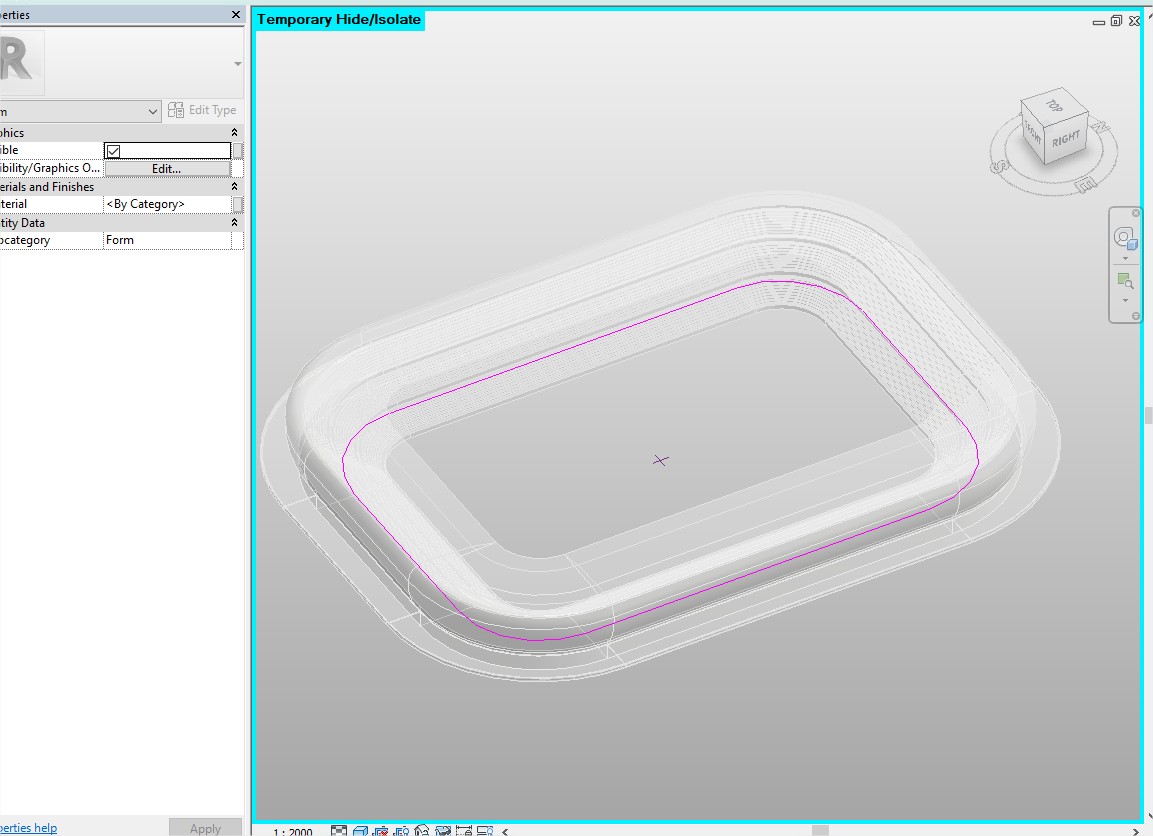

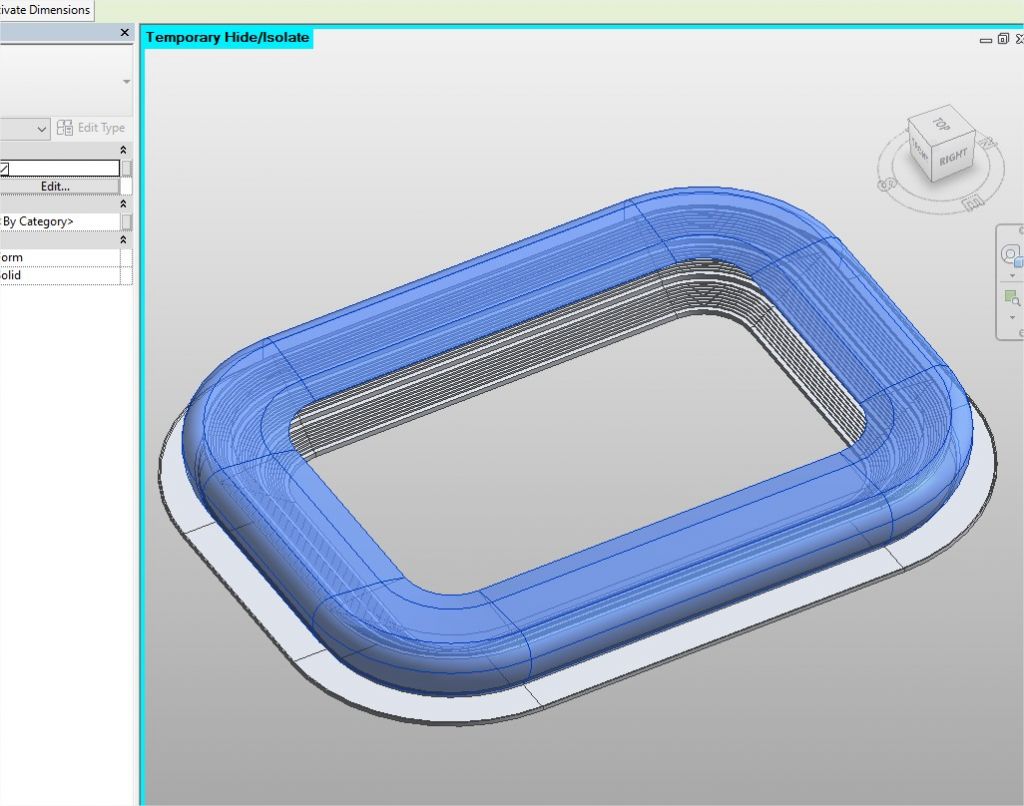

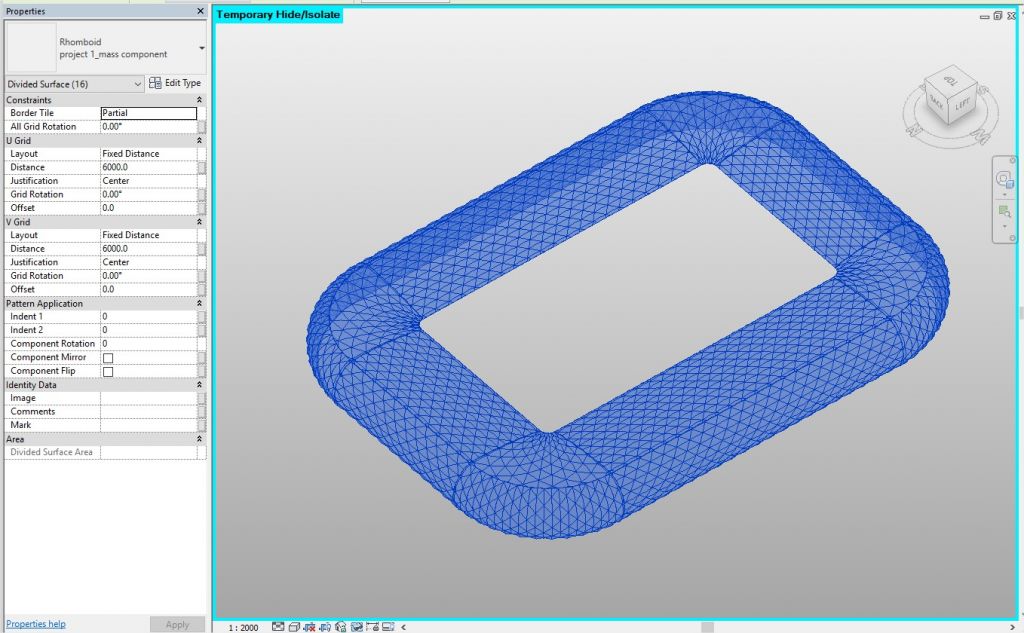

06. Applying the curtain panel

Having selected the receiving faces of the family, the curtain panel was loaded into the family with the swept profile. The selected faces were temporarily isolated so this task could be easier. Next, the rhomboid pattern was mapped to the isolated faces, then the curtain panels were selected and applied to the face after ensuring that the layout was properly mapped.

07. Flexing the parameters

Before this, the stadium types were selected to ensure that the parameters are without errors and flex properly. The horizontal spread family was equally updated to show the pitch outlines and provide space for track events depending on the choice of pitch size.

The Limitations

The process was not without a couple of limitations, one of which was the error feedback “unable to create form due to intersecting files” which the software returned. This was resolved by adjusting the location of the profile. Another impediment was the inconsistency of the curtain panels along the curves which meant that the parameters and rhomboid angles were manually adjusted to fit the sweep.